Pulsed vs. Continuous-Wave (CW) Laser Cleaning: What’s the Difference?

Pulsed and continuous-wave (CW) lasers are the two most common laser-cleaning technologies, each with its own operating principles, advantages, and ideal use cases. Below, we explain in simple terms how they differ and in which situations one outperforms the other.

What Is a Pulsed Laser?

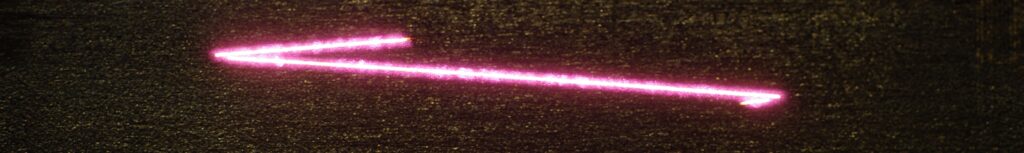

Pulsed lasers emit laser energy in extremely fast bursts—pulses—with small pauses in between. Pulse duration is measured in nanoseconds. The laser beam hits the surface as a series of laser shots rather than a continuous beam.

Thanks to adjustable pulse duration, pulsed lasers can be controlled with high precision. This determines how much heat is transferred to the surface, preventing overheating of the substrate and ensuring safe, controlled cleaning without damaging the base material.

What Is a Continuous-Wave (CW) Laser?

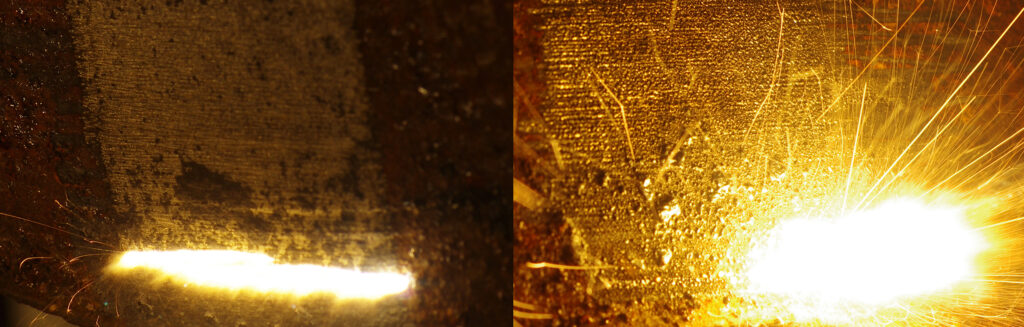

A continuous-wave laser does not operate in pulses; instead, it emits light continuously and uniformly—similar to an incandescent bulb that shines without interruption.

This makes CW lasers faster and more aggressive at removing certain materials, but also leads to higher heat buildup.

Since CW lasers are typically more powerful than pulsed lasers, the amount of heat they generate (and the risk of substrate damage) is greater. For this reason, cleaning delicate or heat-sensitive materials with a CW laser can be very challenging.

Advantages of Pulsed Laser Cleaning

1. Precision

A pulsed laser can remove extremely thin layers, making it ideal for detailed and delicate surface cleaning.

2. Low Thermal Impact

Pauses between pulses significantly reduce heat absorption. This minimizes thermal damage and is well suited for materials that cannot tolerate high temperatures.

3. Versatility

Pulsed lasers work well on a wide variety of materials and surfaces—metal, wood, ceramics, glass, plastics, and more.

Advantages of CW Laser Cleaning

1. Uniformity and Large Coverage

Due to higher power output, CW lasers are effective for cleaning larger surface areas.

2. Effective on Thick Layers

CW lasers remove thicker contamination layers (paint, heavy rust) faster than pulsed lasers.

3. Cost Efficiency

For large-scale projects, CW lasers are generally more economical both to purchase and to operate.

Comparison Table: Pulsed vs. CW Laser Cleaning Machines

| Property | Pulsed | Continuous-Wave (CW) |

|---|---|---|

| Energy delivery | Short pulses | Continuous beam |

| Power range | 100 W – 2000 W | 1000 W – 6000 W |

| Heat impact | Low | High |

| Precision control | Very high | Medium |

| Use case | Delicate, heat-sensitive materials; detailed work | Large surfaces; thick contamination layers |

| Device cost | Generally higher | Typically lower |

| Efficiency | Best for small areas | Best for large areas |

Modern Machines: Powerful, Lightweight, and Mobile

Laser cleaning systems have become significantly more affordable, compact, and user-friendly in recent years:

-

Even 500 W pulsed lasers are air-cooled and highly mobile, weighing around ~45 kg or less.

-

CW lasers at 1500 W are also available with air cooling, but for extended operation a water-cooled system is recommended to ensure better cooling of the laser source and cleaning head.

Laserest OÜ has been active in the field of laser cleaning for over 7 years, helping both companies and private clients find the most suitable solutions for using pulsed and CW lasers.

We share our expertise in both application areas and equipment selection—from analysing your workflow to recommending specific models.

If you need guidance with cleaning tasks or are considering purchasing a laser cleaning machine, we’ll help you make a well-informed and reliable decision!