Laser Cleaning and Wood – How Do They Work Together?

Laser cleaning has become an increasingly popular tool in the restoration field in recent years. Social media is now filled with videos showing various surfaces – including wood – being cleaned using laser light.

In this final blog post of the year, we take a closer look at whether and how laser cleaning is suitable for wood, what must be considered when using it, and in which situations laser cleaning is a better choice than traditional cleaning methods.

Is Laser Cleaning Suitable for Wood?

The answer: yes – but with conditions!

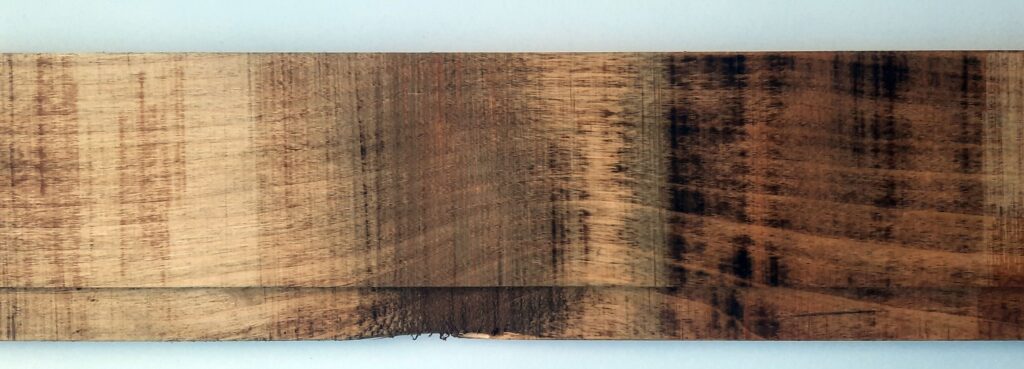

While laser cleaning can be used relatively “boldly” on various metal surfaces, working with wood requires much greater caution. This is because wood is an organic material, and excessive laser energy can cause charring or irreversible damage.

If too much laser energy is directed at a wooden surface, the surface may darken or “burn,” meaning the wood fibers become charred and permanently damaged.

For this reason, laser cleaning is suitable for wood only when used skillfully and with proper knowledge. When the laser parameters are correctly selected, the results can be remarkably high-quality – dirt is removed, and the wood’s natural grain and texture become visible again.

What Types of Surface Coatings Can Be Removed from Wood with a Laser?

Laser cleaning is very well suited for removing the following layers from wooden surfaces:

dirt accumulated over time

smoke and soot residues

thin layers of varnish and paint

superficial stains and glazes

In other words, coatings that have not deeply penetrated the wood fibers and pores.

Laser cleaning can also remove certain wood protection products (such as oils and oil-waxes), but an important limitation must be considered: the laser removes only substances present on the surface of the wood, not those that have penetrated deeply into it.

This means that oils or impregnating agents inside the wood remain and may affect subsequent finishing or color changes.

Which Coatings Are More Problematic for Laser Cleaning?

The most problematic coatings include:

thick and multi-layered paint

water-based varnishes and protective coatings

With thick paint layers, laser cleaning often becomes very time-consuming, as the laser removes material in extremely thin layers. While this process is precise, it is slow.

Water-based varnishes and protective coatings are challenging because laser light is poorly absorbed by these materials. The energy is reflected or scattered, making the cleaning process inefficient or extremely slow.

In such cases, alternative methods (or a combined approach) may be more reasonable.

How Do Different Wood Species Respond to Laser Cleaning?

The effectiveness and speed of laser cleaning depend heavily on the type of wood. Key factors include wood density, color, and the overall condition of the material.

For example:

Birch is light-colored and relatively dense, allowing for slightly higher laser energy settings.

Pine is fairly light but softer, requiring more cautious parameter settings.

Oak is a strong wood, but its darker color absorbs more laser energy, increasing the risk of charring even at lower power levels.

Wood that has been exposed to moisture for long periods tends to become very soft and therefore more susceptible to laser energy, which further increases the risk of damage.

For this reason, laser parameters must be adjusted individually for each wood species. It is essential to test the process on a small area first and fine-tune the working speed and laser energy based on the results.

Why Choose Laser Cleaning for Wood When Alternatives Exist?

Laser cleaning offers several important advantages:

Ideal for relief and carved details that cannot be sanded

No mechanical contact, reducing the risk of physical damage to the wood

Extremely precise control – cleaning can be performed with sub-millimeter accuracy

Preserves the original shape and structure of the object, which is especially important in restoration work

Under the right conditions, laser cleaning is one of the most delicate and controllable methods available for wooden surfaces – something traditional technologies often cannot achieve.

In Conclusion

Laser cleaning is an excellent tool for wood when delicate, precise, and non-damaging surface cleaning is required, particularly for historical or relief-decorated surfaces. However, its limitations must be taken into account – deeply absorbed substances and certain coatings may require additional methods.

When cleaning wooden surfaces, laser technology always demands informed and skillful use.